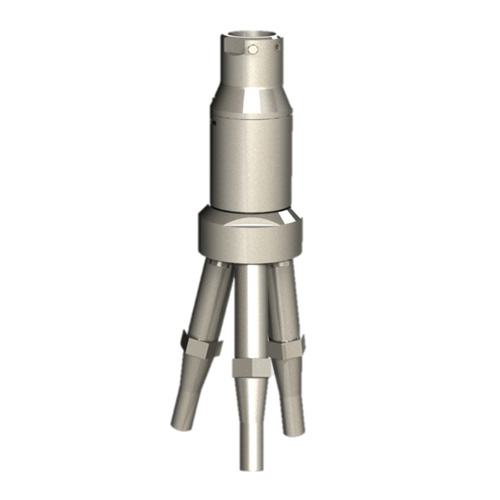

DT (Directional Tank Cleaning Machine)

The Dasic DT is a versatile tank cleaning machine delivering targeted, directional cleaning for maximum efficiency. Originally custom designed to meet the challenge of removing resin scum lines in the Paper & Pulp Industry, the DT can be modelled to meet your most exacting cleaning requirements.

Nozzles angles can be pre-set to wash with multiple jets from 2 to 6 nozzles. Nozzle sizes can be varied on the single head to deliver specific jet lengths to clean different areas of the tank. This is ideal for targeting high impact cleaning jets on areas of dense residue build up such as scum lines, drain points, or tank bottom washing. Shadow studies can be commissioned to ensure existing obstacles of internal structures & pipework are minimized.

The mounting angle of the machine can also be pre-set to ensure maximum coverage where the tank access point is not central. The nozzle head itself can be designed to allow for alternate nozzle combinations to be re-configured / adjusted on-site.

Machine Features

- Bespoke configuration of nozzle number & nozzle angles to target scum lines or tough areas of residue & tank bottom washing

- High impact, efficient cleaning process

- Reduced operational & lifetime costs

- On-site nozzle re-configuration option, providing extended use & flexibility

- Reduced water consumption

- Simple, low maintenance design

Technical Information

- Materials of manufacture:-

- Body 316L Stainless Steel

- Gears PEEK

- Bushes Carbon PTFE

- Max height variable

- Max width variable

- Weight 6.0kg

- Inlet connection 1.5”BSP/NPT

- Operating temperature up to 95°C